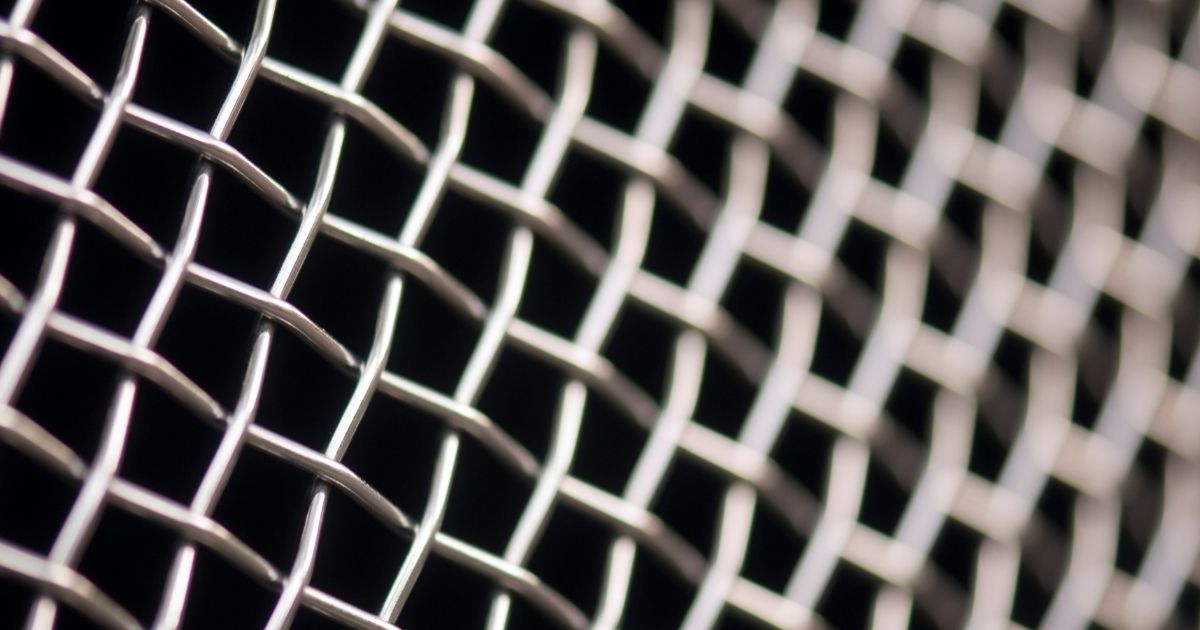

Calendered screen-printing mesh is specially treated to compress and smoothen its surface for improved print quality. This blog explores how using calendered mesh can enhance print quality and precision in screen printing.

Benefits of Calendered Mesh

Calendered mesh offers several advantages:

- Improved ink flow: The calendered mesh has a smooth surface. This allows for better ink flow and more precise transfer. It results in sharper prints and smoother ink coverage.

- Enhanced print quality: Calendered mesh can improve print quality, particularly when printing fine lines, halftones, or high-resolution images.

- Consistent stencil thickness: Ensuring a consistent stencil thickness is essential for successful printing. This can be achieved with a calendared mesh, as it provides an even surface. Proper ink coverage and consistent prints depend on this consistent stencil thickness.

The Calendering Process

This process involves passing the mesh through a series of heated rollers under high pressure. This process compresses the mesh threads, creating a smooth, even surface. Calendered mesh can be produced in various mesh counts and thread diameters, depending on the desired print quality and application.

Choosing the Right Calendered Mesh

Selecting the appropriate calendered mesh for your printing needs depends on factors such as the design, ink type, and substrate material. When choosing calendered mesh, consider the following:

- Mesh count: Higher mesh counts are suitable for detailed designs and fine lines. Lower mesh counts are ideal for bold graphics and solid prints.

- Thread diameter: thicker threads provide greater durability but reduce the accessible area for ink to pass through. Thinner threads offer better detail and ink flow but may be less durable.

- Application: Calendered mesh is beneficial for a variety of applications such as printing fine lines, halftones, or high-resolution images on smooth substrates such as glass, plastic, or metal.

Proper Care and Handling

Calendered mesh requires proper care and handling to maintain its performance and durability:

- Cleaning: Use gentle cleaning agents and avoid abrasive scrubbing, which can damage the smooth surface of the mesh.

- Storage: Store calendered mesh in a clean, dry, and temperature-controlled environment to prevent warping and degradation.

- Tensioning: Ensure the mesh is properly tensioned before use to maintain consistent print quality and prevent distortion.

Calendered screen-printing mesh can significantly boost print quality and precision, especially in applications requiring fine detail or smooth ink coverage. By understanding the benefits of calendered mesh, you can improve your screen-printing process and consistently achieve high-quality results.

Questions on calendered mesh options or want a quote? Contact us.