Conveyor Belts for Textile Printing Dryers: Ensuring Consistent and Efficient Drying

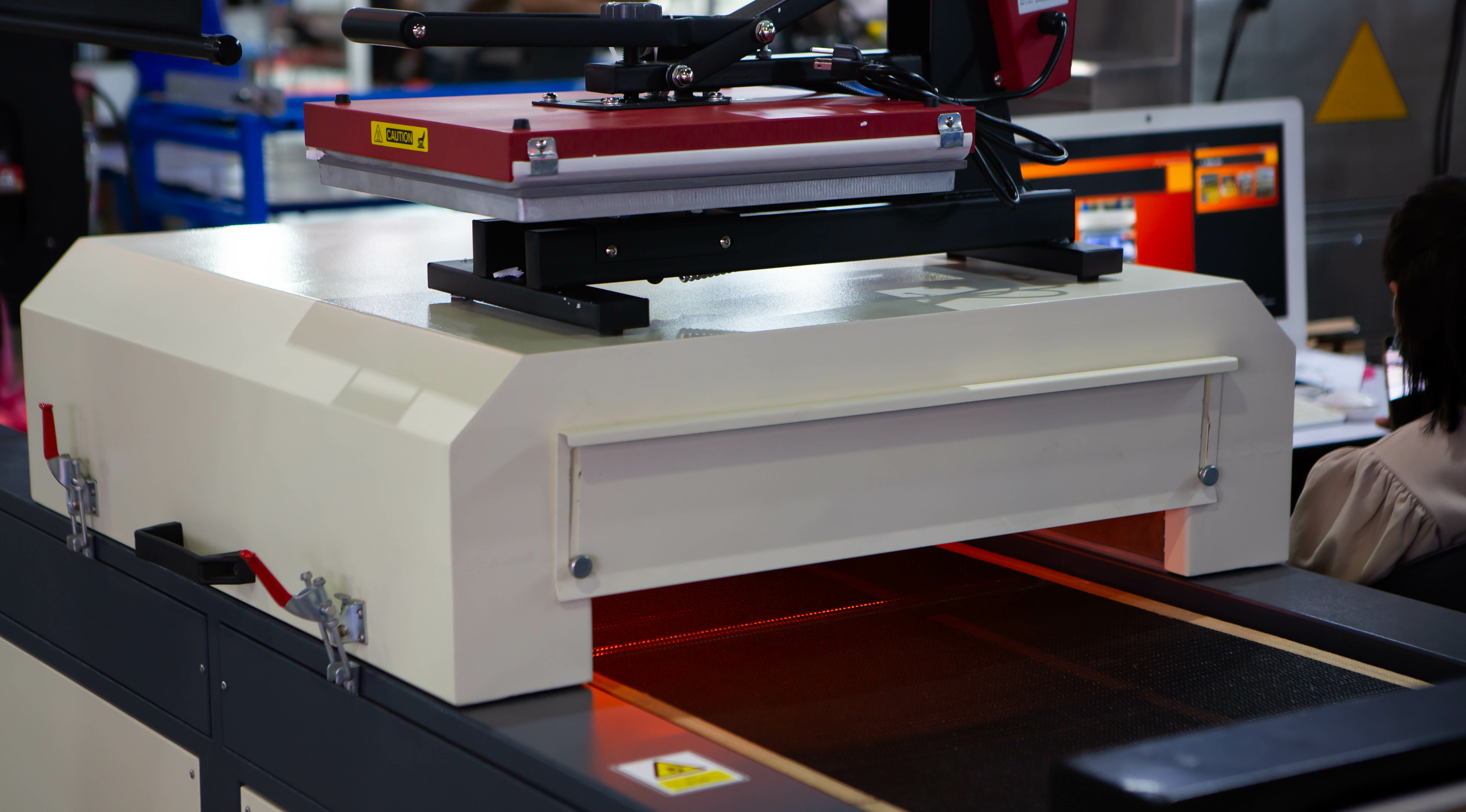

In the screen-printing industry, textile printing dryers play a crucial role in ensuring that printed garments are properly cured and dried. Conveyor belts are an integral component of these dryers, responsible for transporting the garments through the drying process.

In this blog, we'll explore the importance of conveyor belts in textile printing dryers and discuss factors to consider when choosing the right belt for your drying system.

1. Types of Conveyor Belts

Conveyor belts for textile printing dryers come in various materials, including:

- Teflon-coated fiberglass: These belts are heat-resistant, non-stick, and provide excellent durability. They are widely used in textile printing dryers due to their ability to withstand high temperatures and resist ink transfer.

- Silicone-coated fiberglass: Like Teflon-coated belts, silicone-coated fiberglass belts offer heat resistance and non-stick properties. They can be a more economical option but may have a shorter lifespan compared to Teflon-coated belts.

- Stainless steel mesh: For applications requiring extremely elevated temperatures or specialized drying processes, stainless steel mesh belts offer excellent durability and heat resistance. However, they can be more expensive and challenging to maintain compared to fiberglass belts.

2. Factors to Consider When Choosing a Conveyor Belt

When selecting a conveyor belt for your textile printing dryer, consider the following factors:

- Temperature resistance: Ensure that the belt material can withstand the temperatures used in your drying process.

- Non-stick properties: Choose a belt material that resists ink transfer to prevent print defects and maintain consistent print quality.

- Belt tension and tracking: Proper belt tension and tracking are essential for smooth and efficient transportation of garments through the dryer. Select a belt material and design that provides reliable tension and tracking performance.

- Maintenance requirements: Consider the ease of cleaning and maintenance when choosing a belt material. Regular cleaning and inspection are crucial for maintaining belt performance and prolonging its lifespan.

3. Proper Conveyor Belt Care and Maintenance

Proper care and maintenance of your conveyor belt are essential for ensuring consistent drying performance and prolonging the belt's lifespan:

- Regular cleaning: Clean the belt regularly to remove ink residue, lint, and other debris that can affect performance and cause wear.

- Inspection: Inspect the belt for signs of wear, damage, or tracking issues. Address any problems promptly to prevent further damage and maintain consistent drying performance.

- Replacement: Replace the belt when it shows signs of excessive wear or damage, or when its performance begins to decline.

Conveyor belts play a critical role in textile printing dryers, ensuring consistent and efficient drying of printed garments. By understanding the diverse types of conveyor belts, considering factors such as temperature resistance, non-stick properties, and maintenance requirements, and taking proper care of the belt, you can optimize your drying process and maintain consistently high-quality prints.