If you're looking to achieve the best possible results for your screen printing project, choosing the right mesh screen is essential. With so many options available, it can be tough to make the right decision. That's why we've put together a comprehensive guide to help you select the perfect mesh screen for your needs. This guide will help you understand most of the essential factors to consider when choosing the right mesh screen for any project.

Understand Your Design

Before selecting a mesh, it's crucial to have a clear understanding of your design. Consider the level of detail, color gradients, and ink coverage required for your project.

Here are some general guidelines for matching mesh count to your design:

High-detail designs

Choose a higher mesh count to achieve intricate details and fine lines.

Bold graphics and large text

Opt for a lower mesh count to allow for more ink coverage and solid prints.

Halftones and gradients

A mid to high mesh count is recommended for smoother transitions and better detail.

Ink Selection

The type and viscosity of ink used in your project can influence your mesh screen selection. Different inks have different characteristics and may require specific mesh counts to achieve optimal results.

Water-based inks

These inks are thinner and can be used with higher mesh counts.

Plastisol inks

Thicker than water-based inks, plastisol inks usually require a lower to mid-range mesh count.

Specialty inks

Metallic, glitter, and high-density inks typically have larger particles and require lower mesh counts.

-1.png?width=800&height=498&name=Untitled%20design%20(43)-1.png)

Substrate Material

The substrate material you are printing on can also impact your mesh choice. Factors such as the material's texture, absorption properties, and desired print durability should be considered.

Textured substrates

Lower mesh counts are suitable for printing on textured materials, as they allow for thicker ink deposits.

Smooth substrates

Higher mesh counts are recommended for smooth surfaces, as they offer finer detail and a smoother print appearance.

Absorbent substrates

Lower mesh counts can help prevent ink from bleeding into the material by depositing a thicker layer of ink.

Production Speed and Volume

Your production requirements may also influence your mesh selection. Balancing the need for speed, efficiency, and quality is crucial.

High-volume production

Lower mesh counts for high-volume production result in faster ink coverage and production speed.

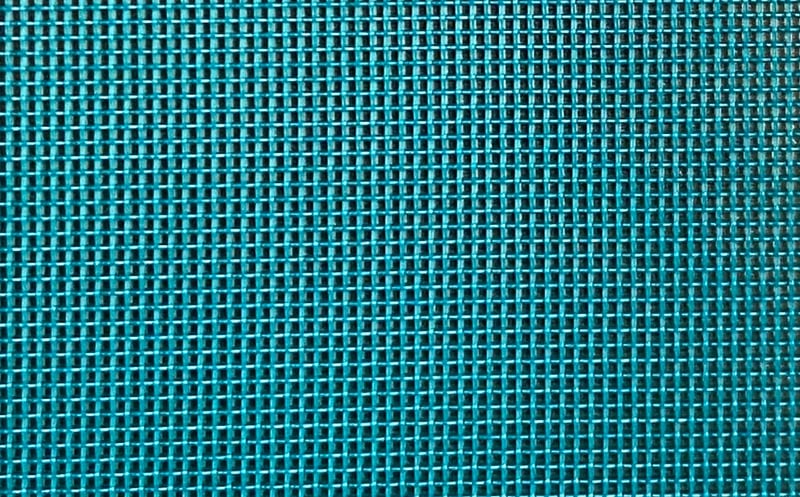

Mesh Screen Material

Meshes are typically made from polyester, nylon, or stainless steel. Each material has its advantages and drawbacks.

Polyester

This is the most widely used mesh material, providing an economical option with excellent tension stability and durability.

Nylon

Nylon meshes are more elastic than polyester, making them suitable for printing on curved surfaces or when using abrasive inks. However, they are less stable when it comes to tension.

Stainless steel

Stainless steel meshes offer excellent durability and tension stability but are generally more expensive and challenging to work with.

Balancing Mesh Count and Thread Diameter

When selecting a mesh, consider both the mesh count and thread diameter. Thicker threads offer more durability but reduce the open area for ink to pass through. Thinner threads provide better detail and ink flow but may be less durable. Striking the right balance is essential for achieving the desired print quality and durability.

Choosing the right mesh screen for screen printing is essential.

When deciding, several factors must be taken into account, such as design, ink type, substrate material, production requirements and mesh material. It's essential to understand these factors in order to select the best mesh screen for your project. This will ensure excellent print quality and efficient production. Keep in mind that experimentation and testing may be necessary to achieve the desired results.